Well, I thought it had been a lot longer since I did any construction, but I see it was only back in February. I really wouldn’t have been surprised to find that I’d gone an entire year without building anything. But, I’m getting ready for winter and more building. To be honest, I’d had second thoughts recently about even continuing with this project. Sometimes it seems like such a massive undertaking, especially when I see pictures of guys attaching the wings and getting flying wires made and rigging done… only to tear it all apart again and then start covering. Covering!! How the hell an I ever going to cover this beast? But then I decide that maybe I’ll keep at it after all. Hey, it’s relatively cheap… so far… as hobbies go. It keeps me occupied for as long as I care to work on it, and nothing bad happens if I let it sit idle for a while. Even a long while.

Over the past few days I’ve been working on getting my absolute pit of a basement workshop cleaned up at least enough to be able to move around and use the workbench. A new water softener installation, a kitchen remodel and a few other household projects meant there was a lot of mess left over, and a whole lot lot of crap got just piled everywhere. Most of it’s cleaned up. Not enough, really, but at least enough for me to be able to take stock of where I am. In hindsight, I suppose I could have, you know, looked at my blog posts, but where’s the fun in that?

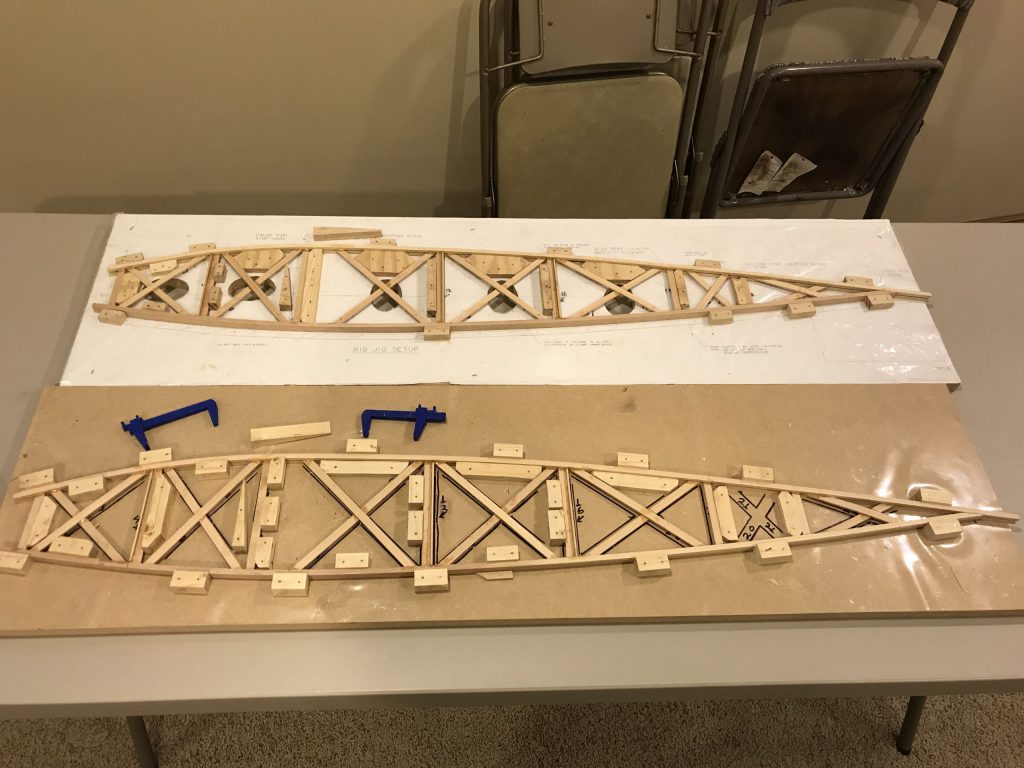

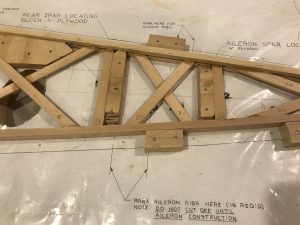

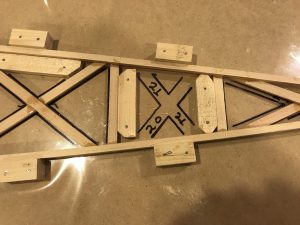

I need 26 normal wing ribs, and they are all done. I need 16 aileron ribs — the same as the normal ribs, but just missing a couple of cross pieces. Of those, I have built ten, so there are six left to build. Then there are 34 false ribs — just stubs from teh leading edge back to just behind the main spar. I’ve built one of them, so 33 left to build. Those should be quicker to build, since there are only about a quarter of the geodetic braces to cut and glue. Unfortunately, each will still occupy a full rib jig — so two at a time is still the limit. Unless… maybe after the aileron ribs are done, I can tear down one of the rib jigs and rebuild it to do several false ribs at a time. I think keeping one rib jig intact would be good, just in case I should ever need to build more ribs for a repair or whatever.

I’ve got a bunch of geodetic brace stock sanded down to the correct thickness. Enough for sure to do the rest of the aileron ribs and get a good start on the false ribs. I’ll probably do half a dozen more, then put the oscillating sander away and maybe knock out a few ribs. I’m starting to get a little fired up again.