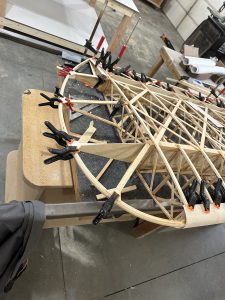

You think you’re about ready to perform some major step, then you step back and realize you’re not as close as you thought… I thought I was about ready to cut out the aileron, but I still had to get the bottom geodetic braces in as well as several of the plywood stiffening strips that keep the aileron bay and aileron from distorting when the fabric gets shrunk around it. Today I did that, I also got the leading edge plywood wrapped around the rest of the way and glued and clamped in place, and added the last of the wingtip reinforcements along with the gussets for all of those.

I started to shoot primer on the torque tube, but the can stopped spraying about halfway through. Super frustrating, as it’s a full can, It’s been in a cabinet in the garage for a while, so I suspect there was a chunk of unmixed solid that lodged in the valve or something. The spray tip is clear, the can is pressurized, but it refuses to spray. Bummer. I found a can of self-etch primer in another cabinet at home, so hopefully that works. I may end up with a torque tube that’s half gray and half white… oh well.

I’ve been cleaning up the Airpath compass while I wait for the new gaskets and diaphragm from Spruce. This one has a light and I didn’t want to use the incandescent bulb, and I’d already broken one of the wires anyway… so that path was blocked. I had ordered some LED bulbs from Amazon – they are commonly known as type 74 LED bulbs. The spec sheet showed they are about 0.7″ long and 0.23″ diameter. Those arrived today, and they do fit inside the bulb socket. I soldered the wires onto the new LED assembly “backwards”, or with the wires running along the body of the light so the tip goes in first and the connector end faces outward. This puts one of the three chip LEDs directly over the little red window that illuminates the compass. I had to remove about 1mm of the tail end of the lamp assembly so the little cover would close, but with that done it’s near perfect. I’ll get more pictures as soon as the paint I used to touch up the worn spots on the lamp cover is dry. The gaskets are supposed to be here on Tuesday, and I’ve got a can of mineral spirits I can use to fill it… not being willing to spend the extra money on UPS shipping for a pint or so of “compass fluid”, which from what I can tell is basically… mineral spirits.