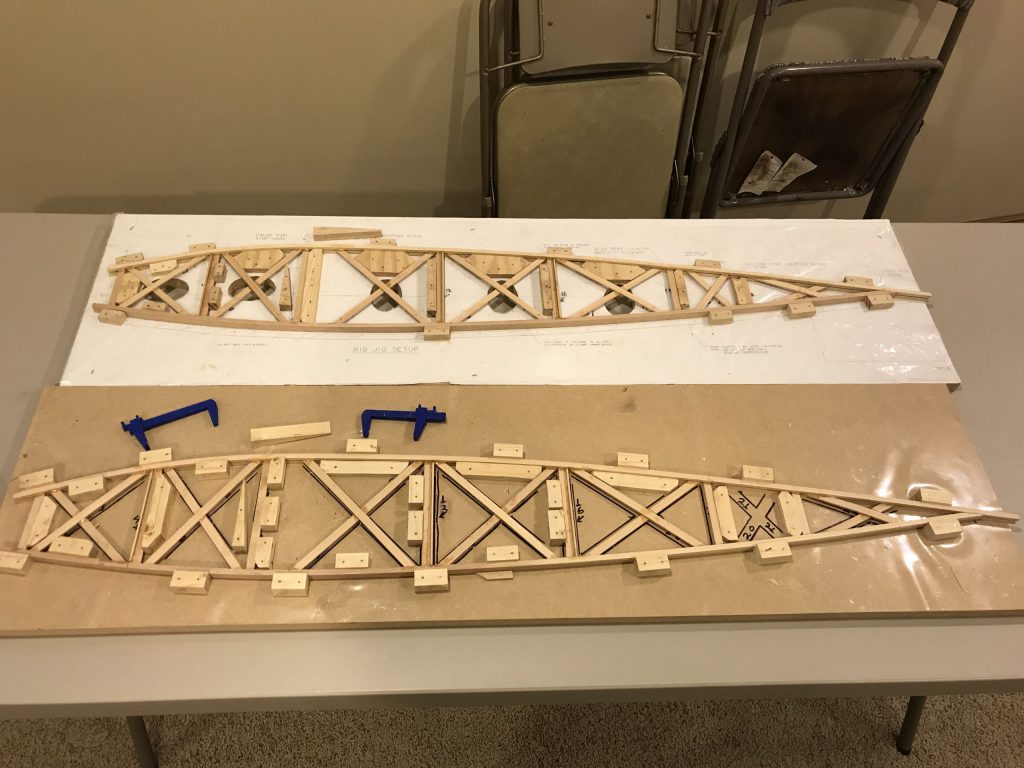

I’ve been wanting to get back to building ribs. The garage bench has been piled too deep to get anything done, and now it’s been below zero for over a week solid. Insulation or no, it’s damned cold out in the garage. Too cold for epoxy to cure, and too cold to work.

So… there’s a perfectly good work bench down in the basement. 8′ long and rock solid, built by Dad back in the 1960s. It’s been pretty much completely covered up for the past several years with a collection of parts, partially-disassembled or -assembled prototype projects and assorted debris from the side business I was running, plus a CNC router that took up about 3′ of it. I have cleared most of it off (much of it into a trash can). The CNC machine is shelved for now; I’ll maybe resurrect it when needed at a later date. It will probably come in handy for cutting the instrument panel and/or nose ribs.

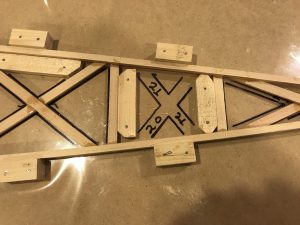

The next issue is containers for the geodetic rib braces. There are 24 braces used in each rib, all of which are of course slightly different. Just enough so that none are interchangeable. I was using paper cups to hold them in the garage, but it’s a completely unsatisfactory solution. In the basement I think I’m going to try stapling taller plastic cups along the back edge of the bench and see how that works.

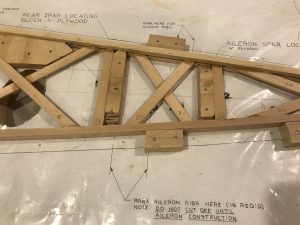

I’m not moving power tools down there from the garage, so new geodetics will be cut with a razor saw. We’ll see how that works out… it’s one of those jobs I wish I could set up a machine or fixture to do. It’s 24 different lengths with over 40 different angle cuts, so I’m not sure how I’d make that work. Even cutting them out in batches on the band saw meant fine-tuning each one with a sanding block before assembly. It’s fiddly work and tedious as hell. Classic gusseted ribs would be a whole lot faster and easier to build. If I were starting this over I’d probably just depart from the plans and build them all that way; I’d probably have them all done by now.