Yesterday (2/16) I cut and glued in some corner blocking I had missed on each end of the aileron and the ends of the aileron bay. Lesson learned: that would have been a lot easier had I done it before the geodetic bits and plywood stiffeners had been installed.

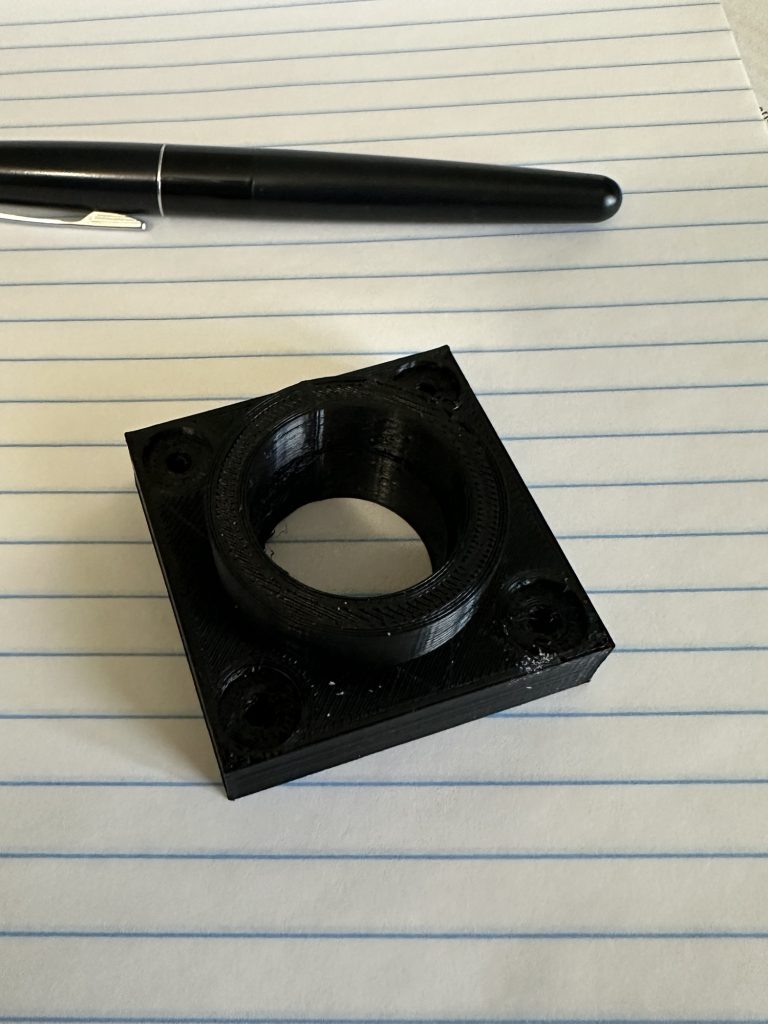

I’m getting to the point where I kind of need the torque tube bearing blocks installed. Then there are the 3/8” spacers, which the plans call out as pieces of PVC pipe. I figure, since I’m going to CNC machine the bearing blocks anyway, why not just make those and the spacers one piece? I pulled up the design in OpenSCAD and added the spacer. I gave it a slightly larger ID than the bearing block so it doesn’t add drag to the aileron control. I 3D printed a couple samples to use for fit & function testing. If that goes as expected I’ll get a chunk of 1” UHMW and pass the design file to Stu for machining. I’d planned to use some 1/2” UHMW I have for the bearing blocks, but I’ll keep that for now and use it for something else.