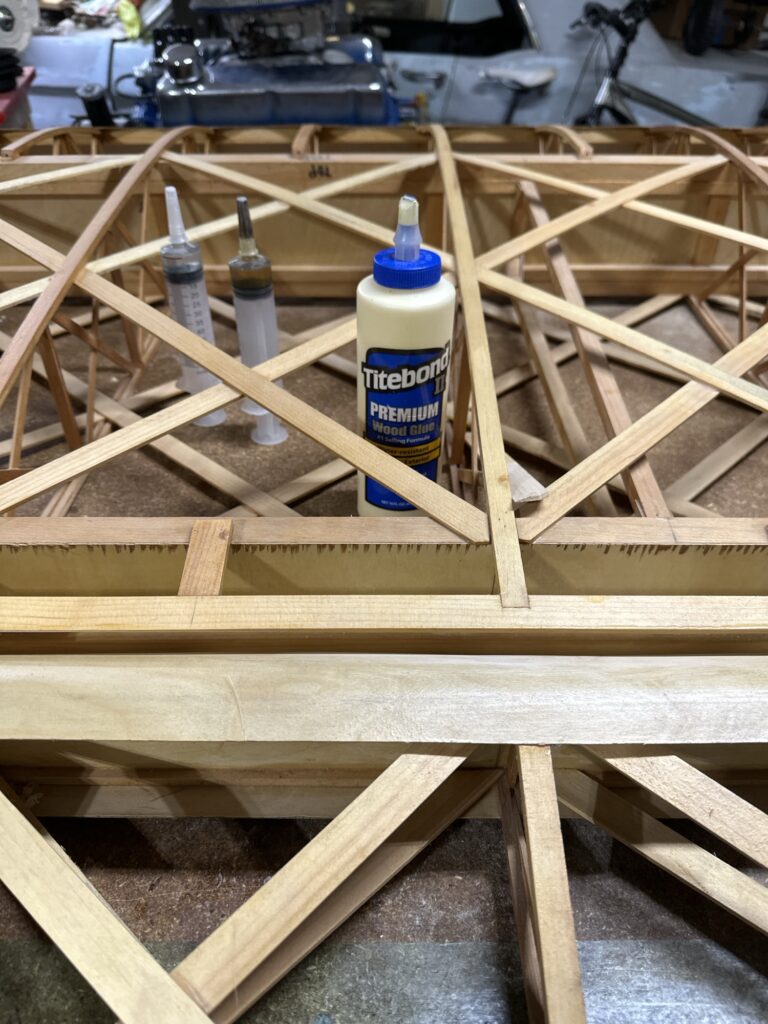

My latest hardware order from Spruce should arrive tomorrow, so I can finish the bracket attachment and have the wing ready to go to the hangar so I can get the other one brought home.

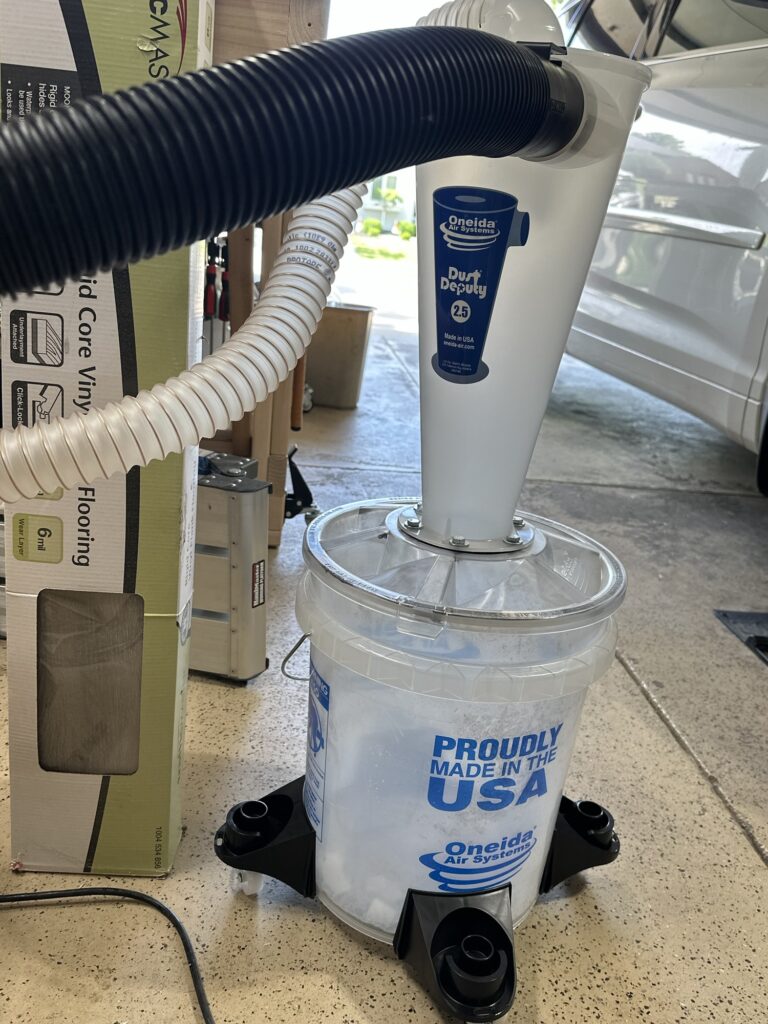

It’s been oppressively hot and humid for the past several days. It’s just a fact of life in Nebraska, as is bitter cold in winter that leaves the garage too cold for epoxy to cure. I’ve been threatening to do this for a while now, but finally my new mini-split heat pump should arrive tomorrow. Unfortunately some of the other items won’t be here until Thursday and Friday, so I may or may not be able to get it installed and working before Friday. If you’re contemplating doing this, the only thing I’d change (thus far) would be to order the mounting bracket for the outdoor unit and the line set cover from Amazon instead of Tosot. Silly me, I figured that stuff would all ship together, or at least from the same place. The mount for the condenser, which I pretty much HAVE TO have before installation, is coming from California and will arrive a full two days later than the rest of the stuff coming from Houston. Dammit. I’d be lying if I said I hadn’t thought about just ordering one from Amazon and using it instead, but the only ones they can deliver tomorrow are far less robust than the one I paid more for… so I guess I’ll just wait.

It’s a 12,000 BTU unit from Tosot. According to the manufacturer it has a SEER of 24.5 for cooling and HSPF or 13 for heating, which is incredible. It’s supposed to cool with outside ambient temps as high as 122 F, and heat with outside temps down to -22. Let’s just say that I’ll believe those numbers when I see the performance and electric bills to match. Still, even if it doesn’t hit all of those numbers it should be pretty good, and the manufacturer (Gree) seems to have a good reputation. It also has an ERV, or Energy Recovery Ventilator, which will ventilate the garage with outside air while saving some of the energy that would normally be required. I figure since the garage is where the occasional pipeful of tobacco gets smoked (and my darling wife’s horrific cigarettes) that should be a nice addition.