A while ago, I picked up a used Westach quad gauge. it looked like a great deal… oil temperature, oil pressure, CHT & EGT in one round gauge. What I found was that it’s an older gauge, though in excellent condition — almost like brand new. The only problem is, it’s designed to use an oil pressure transducer that is no longer produced. 0 to 100 PSI, with an output of 0 to 50 mV. You can get transducers like that, but they cost a few hundred bucks.

Fortunately, there are other transducers that are dirt cheap ($20 and below) that can be adapted to work with the Westach gauge. I found some that have a 0-5V output, and looking at the spec sheet they actually output 0.5 to 4.5V. They also require a 5V supply, and I think the gauge supplies 12V nominal. So… we have two tasks. Supply the transducer with 5V regulated DC, and convert the 5V ouptut to 50mV. Easy!

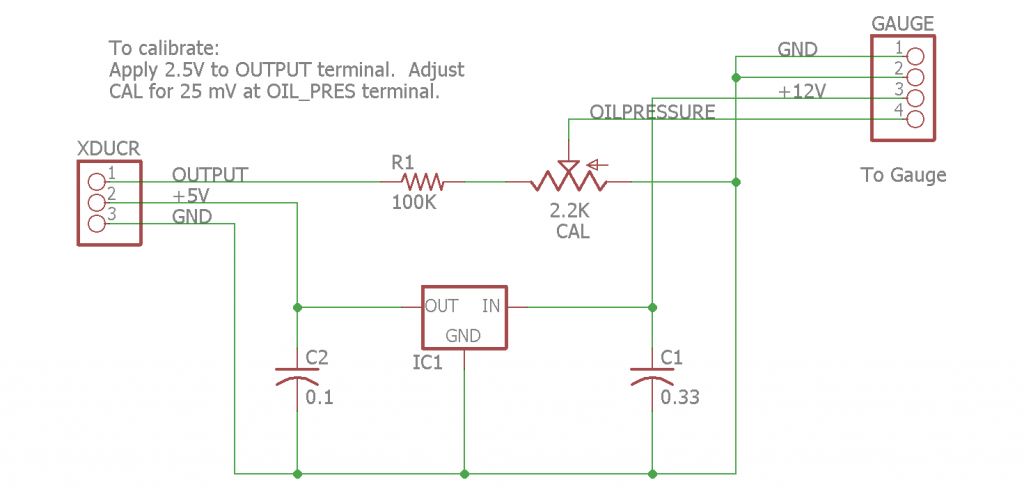

Below is a schematic for a little interface board to do the job. A common 78L05 regulator supplies power to the transducer. A simple resistive voltage divider does the 100:1 voltage conversion. I used a 100K Ohm fixed resistor, and a 2K Ohm trimmer. That way you can calibrate the divider to account for resistor tolerances. Apply 2.5V to the transducer side, and adjust the gauge side for 25 mV. There will be some non-linearity near the high and low ends of the scale, but that’s OK in this case. We don’t need an absolutely accurate oil pressure indication, more of a relatively good indication within a reasonable range. once you get very low or very high, the exact numbers aren’t really important.

Really, it was a great deal. A new similar gauge would cost over $800. Individual small gauges to do the same jobs would cost several hundred and take up a lot more panel space. I’m pretty happy with this one.