Mostly small things over the past week. I cut and installed some more corner blocking that I didn’t get done before, tested a couple new iterations of the bearing block/spacer, and fine tuned the aileron to the opening. Along the way I’ve noted a few new lessons learned…

- Never trust the plans, or the supplemental sheets included with them. They’re often inaccurate. Like the AL bracket diagrams that call out 3/16″ holes when they will get 1/4″ AN4 bolts… and on and on.

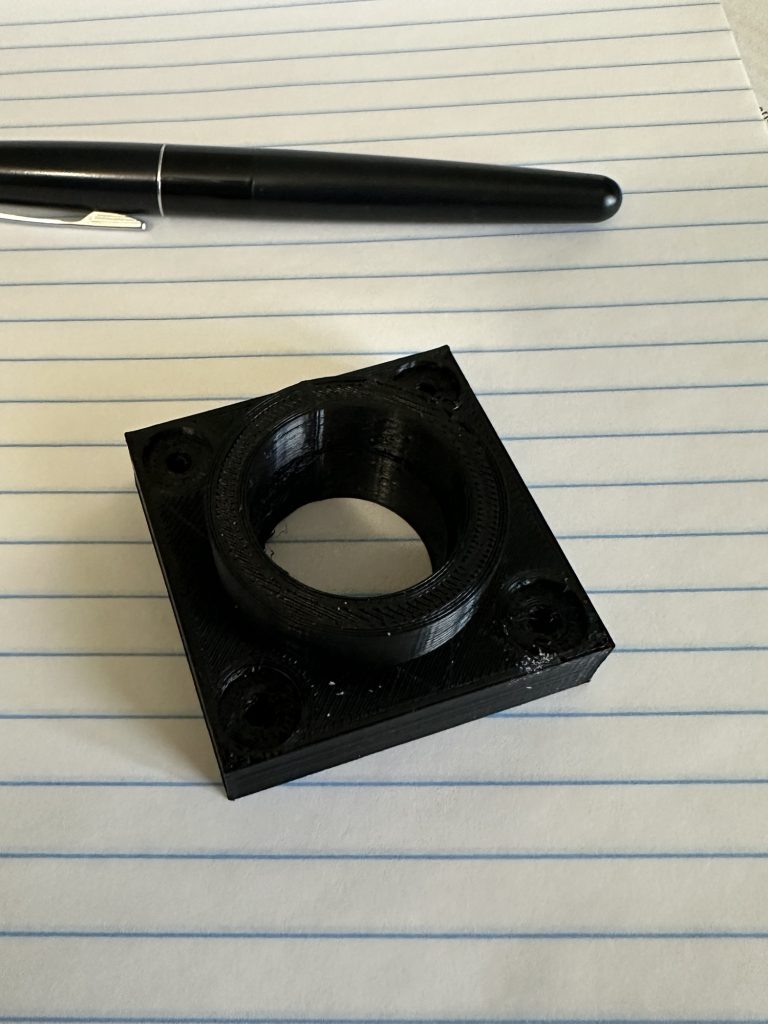

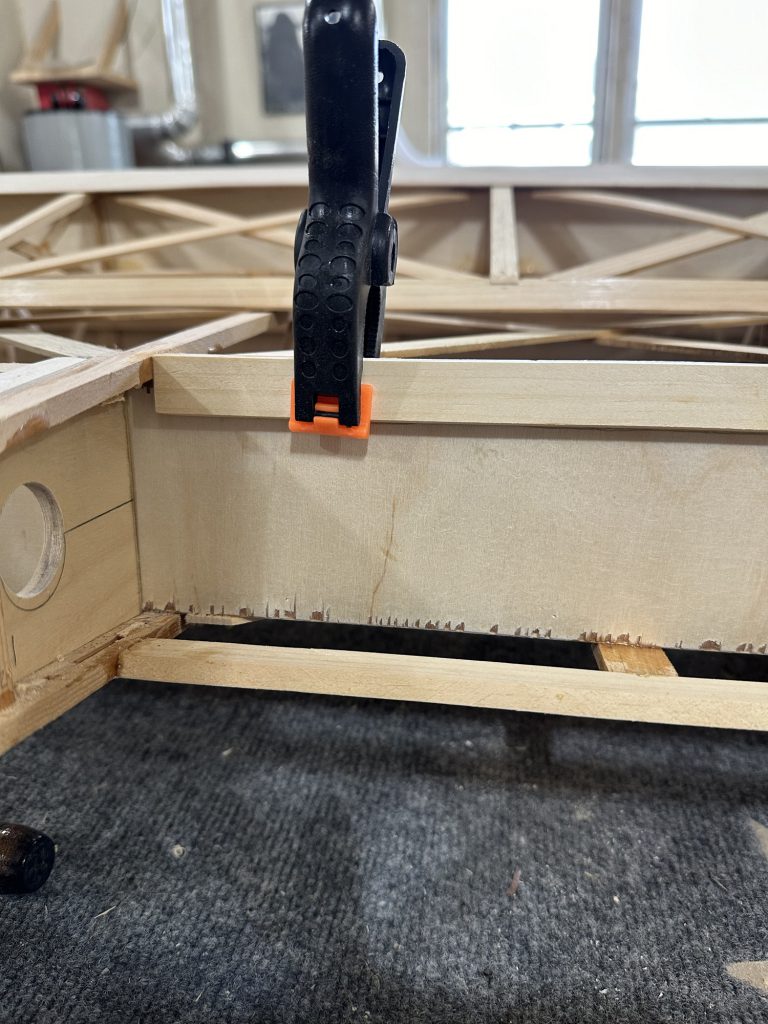

- Get the torque tubes in place, holes moved or enlarged where needed, and bearing blocks in place and holes drilled before cutting the ailerons from the wing. Otherwise it’s just a bitch getting everything aligned after the fact to locate the bearing blocks. This of course goes along with correcting all of the many problems with the holes that are pre-drilled in those plywood parts.

- Make sure all of the corner blocking is installed around the aileron bay as early as possible, and certainly before installing the CW40 plywood stiffeners, aileron leading edge skin, and so on.

- Go over the plan sheet more often and in greater detail to make sure I don’t miss anything that will be a pain to install later on… like corner blocking that would be much easier to plane or sand to shape than to try to cut to match odd angles.

- Install the compression struts before the geodetics! That cost a couple hours of added time working through tight openings.

Not necessarily a “lesson learned”, but something I’d like to explore. All of the ribs ended up needing a 1/8 shim between the top rib cap and the main spar. Rather than shim them with separate pieces, I want to see if I can maybe cut and install the geodetics at the same time the ribs are glued, or something. Or possibly just use temporary shims, and glue the top cap to the spar as the geodetics are installed. It could lead to neater and better construction.